Время задержки блеска твердой поверхности акриловой кислоты влияет множественные факторы, и ее специфические характеристики должны быть проанализированы в сочетании с условиями испытаний и характеристик формулы:

Влияние формулы и процесса отверждения

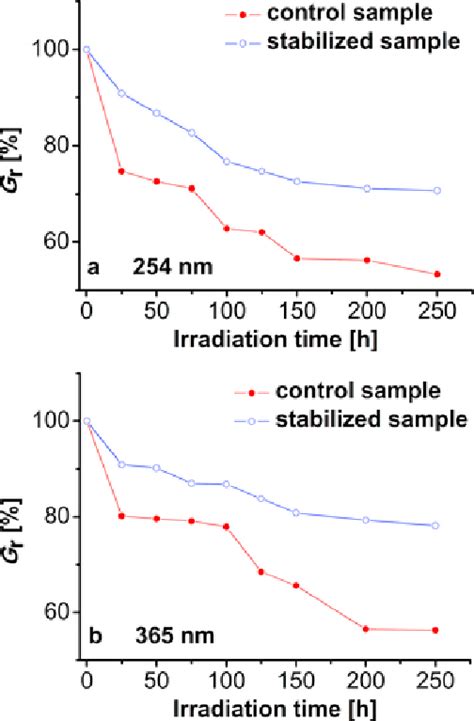

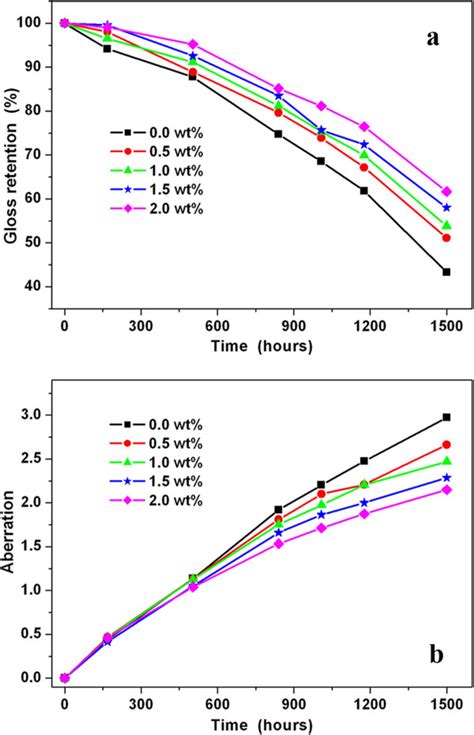

Время хранения акриловых покрытий блеска тесно связано с системой смолы, типом отверждения и процессом строительства. Например, формула, которая использует высококачественное акриловое латексное сырье и оптимизирует условия отверждения, может поддерживать стабильность блеска в течение относительно долгого времени в стандартных условиях испытаний (например, 25 ℃ и 50%RH). Если Ультрапидативные добавки вводятся в формулу, ее блеск может оставаться неизменной без значительных изменений при долгосрочном воздействии солнечного света (например, 500 часов 1000 Вт солнечного света).

Роль экологических факторов

Влажность и температура окружающей среды оказывают значительное влияние на время удержания блеска. Например, частота ослабления блеска акриловых покрытий, применяемых в среде с относительной влажностью не более 85%, снижается более чем на 30% по сравнению с тем, когда влажность слишком высока. Кроме того, если покрытие вступает в контакт с водой до того, как оно будет полностью вылечено, особенно в темных или низкотемпературных условиях, глянец может быть преждевременно снижаться из-за поверхностных дефектов.

Стандарты теста и результаты различий

Время хранения блеска варьируется в рамках различных стандартов испытаний. Например, в соответствии с ГБ/T9754-2007 Стандартно, когда начальный блеск акриловых покрытий, измеренный с помощью углового измерителя глянга на 60 °, составляет ≥80 °, он может упасть примерно до 70 ° в условиях моделируемого естественного старения (например, 1000 часов воздействия ксенонной лампы), но конкретная степень ослабления должна регулироваться в комбинации с формулой и процессом.

Практические применения: техническое обслуживание & Поверхностная обработка

В практическом применении время удержания блеска акриловых покрытий также влияет лечение субстрата, толщина покрытия и методы обслуживания. Например, недостаточная чистота поверхности субстрата или неровной толщины покрытия может привести к быстрому снижению местного блеска. Регулярная очистка и избегание механических царапин могут продлить время удержания глянцевого покрытия на несколько лет.